Precision in Modular Design

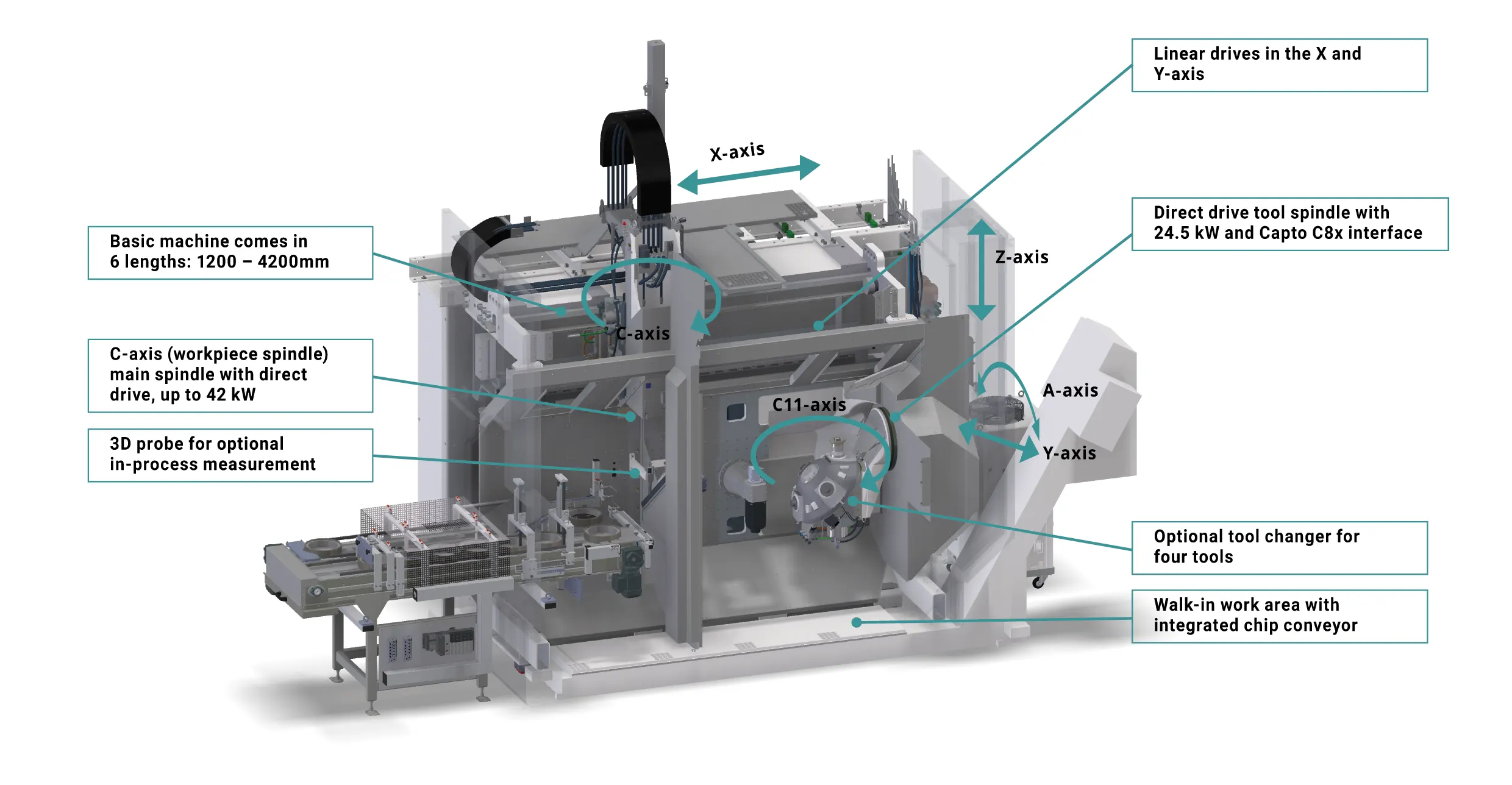

Profilator V-Type

Features

- Modular machine platform in a compact design for gear production

- Maximum flexibility due to the modular design, configurable for a wide variety of machining processes (e.g. Scudding®, hobbing, pointing, cycloidal milling, chamfering and deburring)

- State-of-the-art linear drives in the X and Y-Axis with torque-drive in the A-axis:

– High machine dynamics for short cycle times

– Highest levels of accuracy and low maintenance costs due to backlash-free and wear-free linear drives

– High machine rigidity for HARD SCUDDING® application - Optional tool changer for maximum machining flexibility

- User friendly interface for easy setup and programming

- Industry 4.0 capable, expandable with additional sensors for machine monitoring

- Multiple automation concepts available

- Easy setup and access due to open walk-in work area

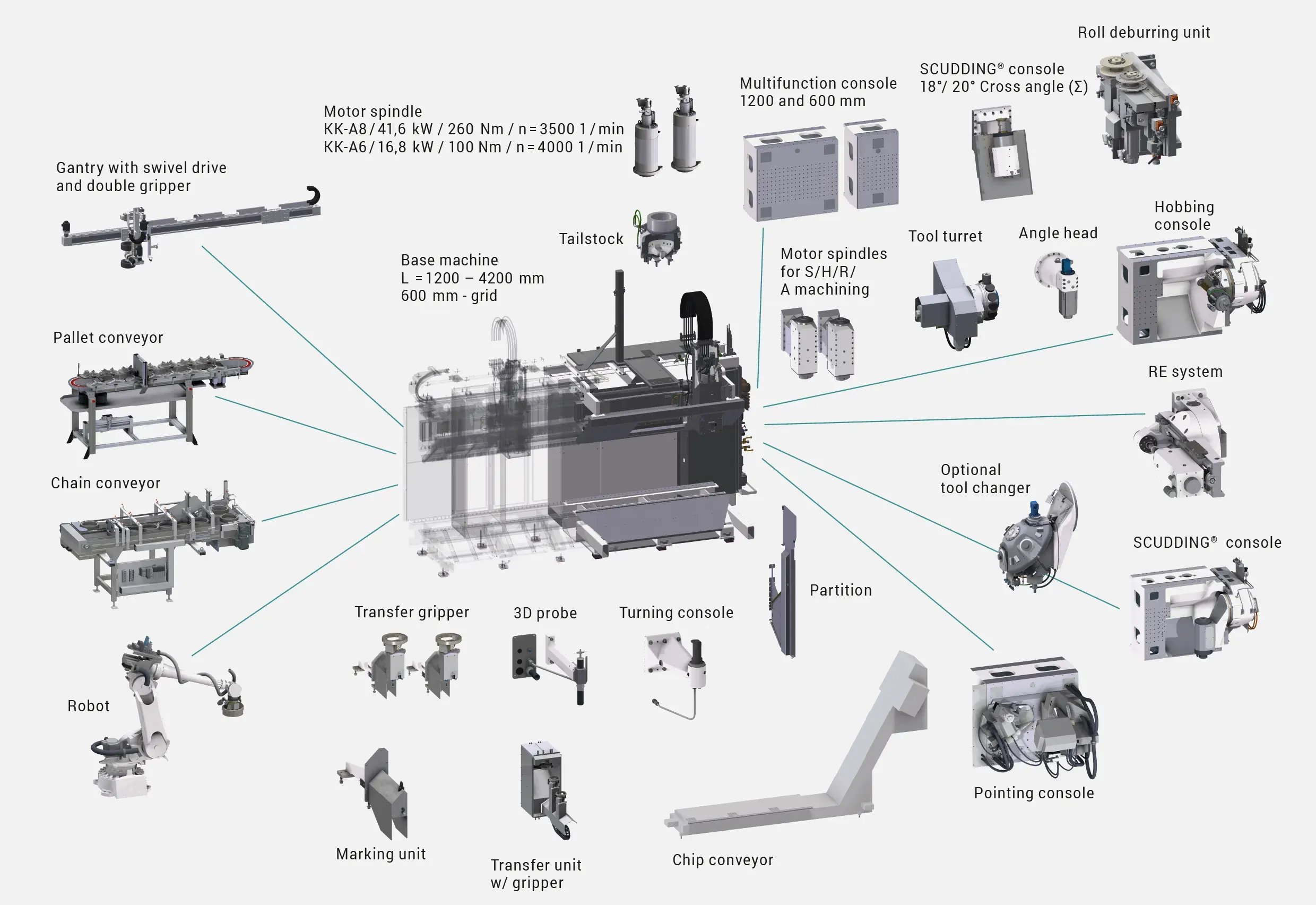

Modular Components for Single- and Double Spindle Machines

Configuration Example

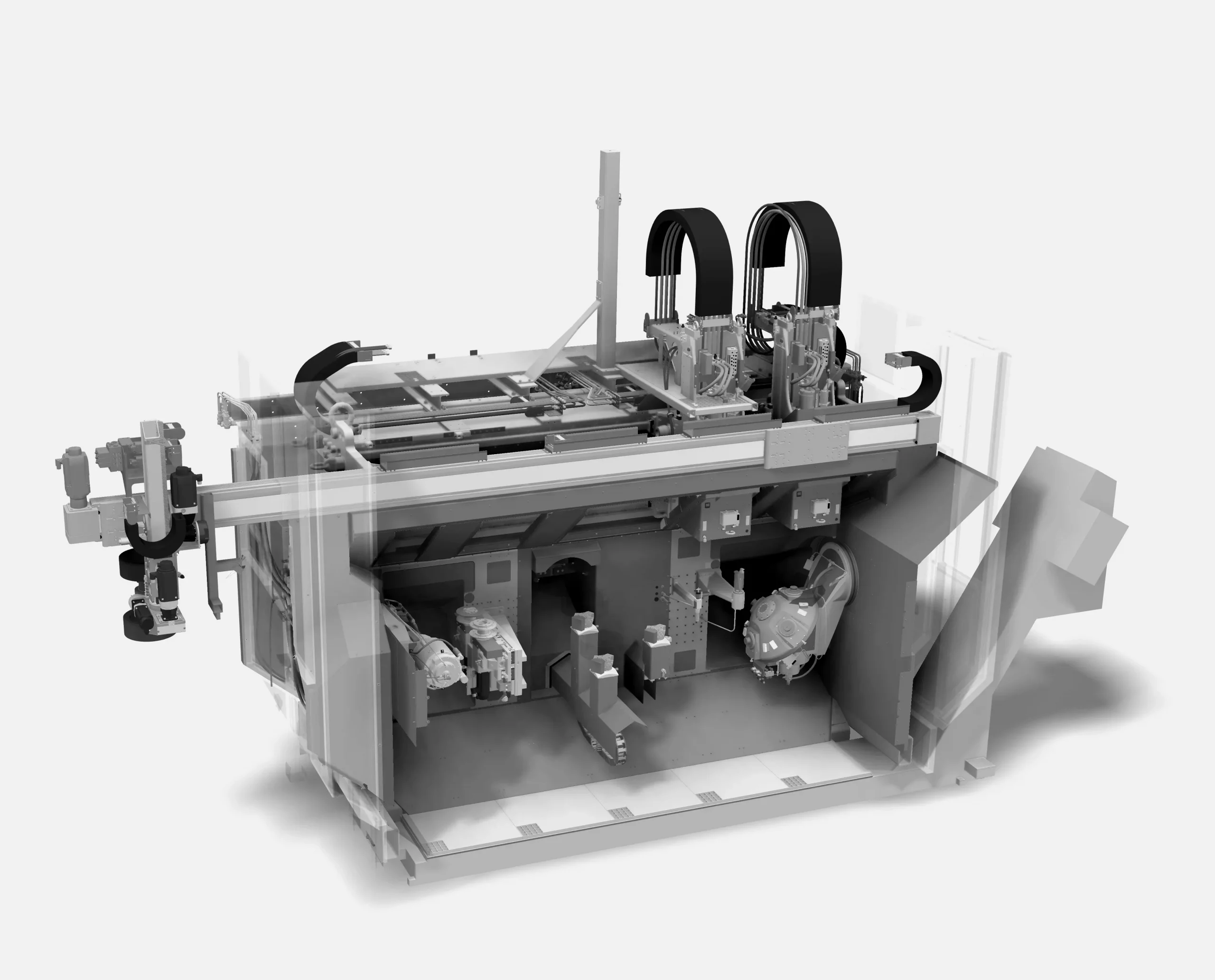

Configuration example for a SVE-330-VL-Twin for the machining SCUDDING®, hobbing, deburring and chamfering.

The optional tool changer allows sequential machining with Scudding®as well as the integration of secondary processes such

as rotary chamfering and many others.

Profilator 300-V

the perfect machine platform for your gear cutting tasks and of course also for e-mobility

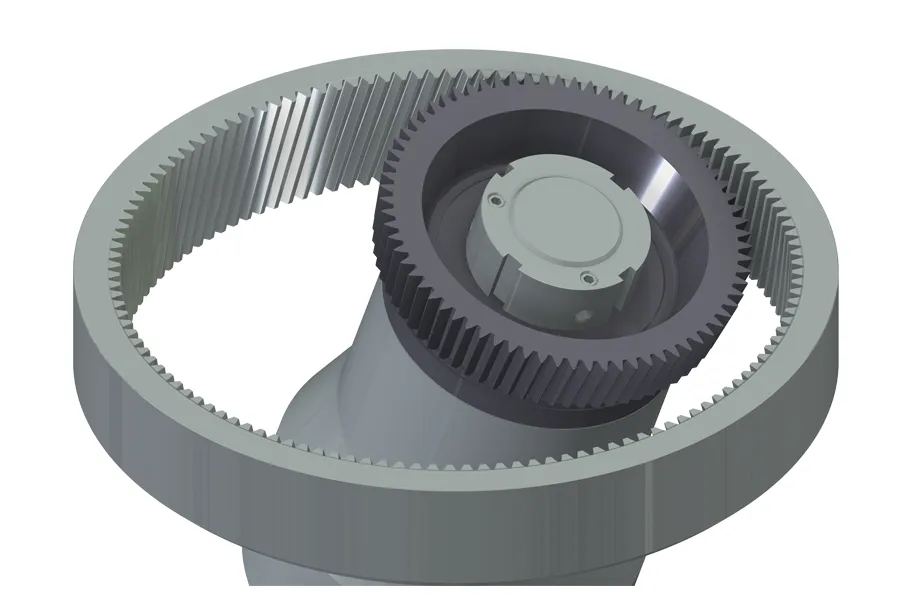

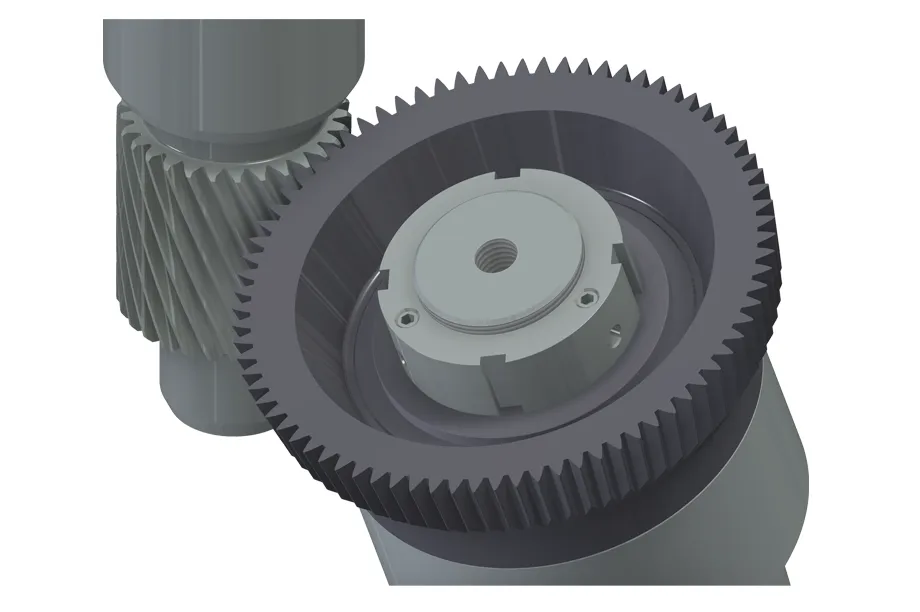

Scudding® of Stepped Gears

Machining of parallel gear profiles with undercut, both gears are

machinable with a double tool

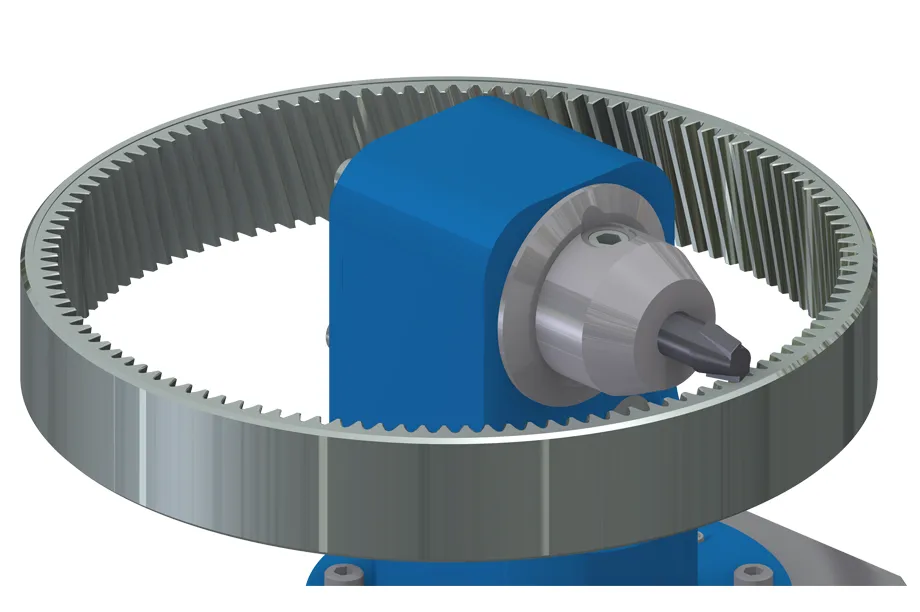

Scudding® of Internal Gears

Cost-efficient production of internal gears

with high flexibility

Chamfer Cutting

Chamfering of the entry and exit side by cutting in one setting with the Scudding®. Fast and precise chamfering process with minimal space requirement

Scudding® of Shafts

Production of rotors, drives, and shafts