Advancement through technology

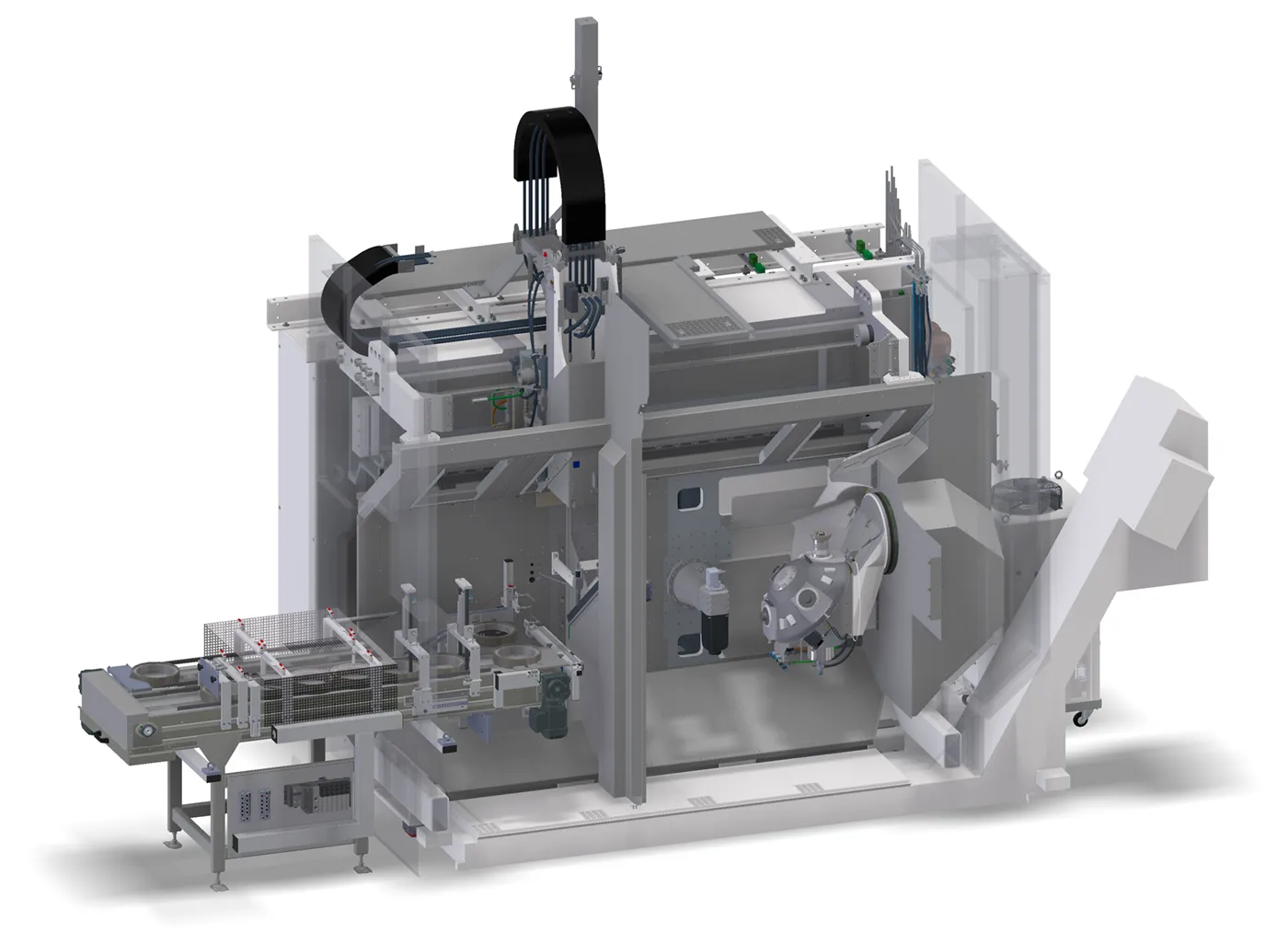

Profilator has developed machining concepts and machining processes which are exactly coordinated to the requirements of the customer. High precision, flexible production processes, short cycle times, low investment and operation costs.

Depending on the machining task, we combine the different machining modules for gear cutting, cycloidal cutting, pointing, shifterstops or deburring into an efficient customer solution. The freely programmable tool-workpiece-synchronisation offers the best possible flexibility.

Technologies

SCUDDING® Quality meets Speed

Internal and external gears

Scudding® is a continuous gear cutting process. Many different tooth variations

can be produced with SCUDDING®. Involute profiles for gears (rings – pinions) along with non-involute and non-symmetrical profiles can be produced for pulleys and block wheels. The Profilator machine concept allows the production of both internal and external gears using SCUDDING® all on one machine.

More …

Cycloidal cutting

The polygon milling unit is used to machine face slot/castle teeth in automatic transmission parts. The revolving cutter head is synchronized with the workpiece spindle can create many possible tooth geometries (e.g. a front clutch), which can also be deburred with additional tools in the same processing step.

More …

Gear & Spline Cutting

The modular system can accommodate fly cutter or hob process. When using a fly cutter tool, machining is carried out with indexable inserts, which produce spline gears, short gears and front gears very economically.

More …

Pointing

The pointing unit can be operated via a rotary or indexed process. To produce different pointing angles, both pointing units can be adjusted during the cutting cycle using a total of 10 NC axes.

More …

Pocket Groove Milling

With the PGM, freely programmable contours can be introduced on both sides into existing tooth flanks by means of synchronous machining.

More …

Chamfering

For the chamfering of gears, Profilator offers a chamfering unit for cutting processing in one clamping with the SCUDDING®, which allows a fast and very precise chamfering process to be integrated into the machine with little space requirement.

More …

Chamfering and Deburring

For the Chamfering and deburring of splines, gear wheels and shafts. The optimal modular system offers the user clear advantages over conventional deburring machines.

More …

Process Technologies

Splines

We offer different gear cutting processes for gear cutting with spline gears:

Depending on the gear cutting job and performance requirement of the customer, the most suitable process can be chosen from the available gear cutting processes – fly cutting with carbide inserts, hobbing, gear skiving and SCUDDING®.

Face gears

Different face gears can be cut on our machines with different gear cutting processes:

Clutch gears, sensor splines and Hirth gears are created with the cycloidal cutting process. The crown gear is done using SCUDDING®.

Special gears

To produce special gear forms in synchromesh and gearbox parts for trucks and cars, we offer machines for all required machining.

Depending on the requirement, an optimal machine configuration can be put together for the customer using our modular systems shifterstops, pocket groove milling, pocket cutting and pointing. This ranges from the single spindle machine with the greatest flexibility to the double spindle machine with the shortest cycle time.

Advantages of Modular Design

individual modification

different processes

processes run parallel

easy to maintain

operator and maintenance friendly